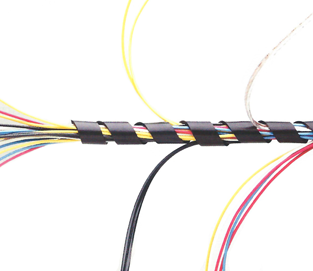

It’s versatile and flexible, capable of organizing cables or wires while protecting them from abrasion. Also known as spiral wrap or spiral tubing, spiral cable wrap is commonly utilized for electrical work to keep bundles of cabling organized. Unlike cable ties, spiral cable wrap doesn’t stress …

Heat Shrink Tubing Tips & Tricks

Heat shrink tubing – sometimes referred to as electrical shrink tubing – protects and organizes wiring within electrical arrays. It’s primarily used to prevent damage to electrical components, protecting against hazards like abrasion, dust and moisture, all of which can damage wiring and cause el…

How Spiral Wrap is Used in Boat Manufacturing

In a car, the engine is normally running when anyone’s in it, so the alternator is producing most of the voltage to run electrical equipment in it. In a boat, however, electrical appliances are more likely to require power when the boat’s anchored with its engine off. For this reason, the electri…

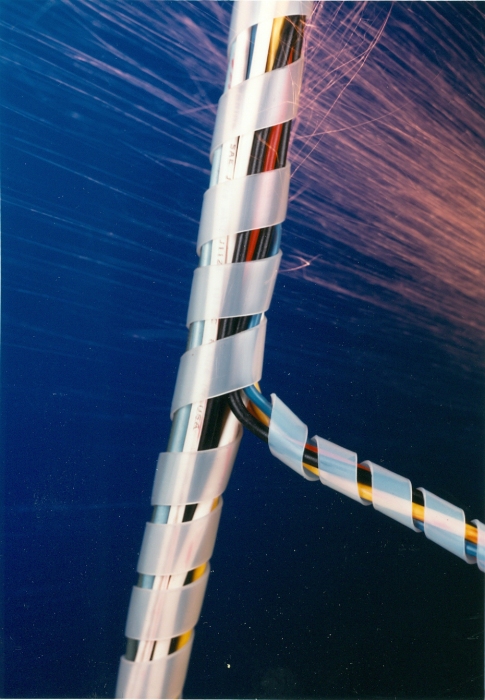

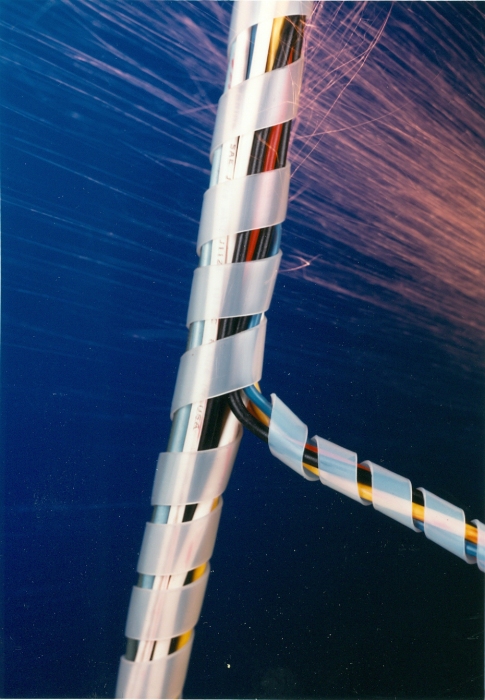

How Spiral Wrap is Used for Abrasion Protection

Spiral wrap – known also as spiral cable wrap, spiral wrap tubing or spiral wire wrap – serves a number of important purposes. One key function of spiral wrap is to protect wires or hoses against abrasion. However, unlike other methods for protecting cables or hoses, due to its design spiral wrap…

How Spiral Wrap is Used for Bundling

When two or more electrical cables or wires are bound together, the process is often referred to as bundling. There are several other terms used to describe this method for organizing wiring, including cable management systems, structured cable systems or simply structured wiring. Bundling serves…

Popular Heat Shrink Tubing Material

Commonly used in electrical setups, heat shrink tubing insulates electrical components from harmful elements in their immediate surroundings. This includes protecting against abrasion, dust, moisture and other environmental factors that can damage wiring or cabling. It’s sometimes referred to a…

FEP Corrugated & PTFE Convoluted Tubing, and AWG Sizes of PTFE Tubing – Applications & Benefits

With methods originally developed in 1966 by a Pennsylvanian plastics company, plastic corrugated tubing came into use in the United States in 1967 as a means to transport liquids. This followed the invention by Germans of corrugation extruding machines earlier in the decade. Fluorinated ethylene…

Spiral Wrap Tubing – Benefits & Applications

Regardless of the industry, protecting lines through which electricity or liquids pass increases safety and productivity in work environments. OSHA (Occupational Safety and Health Administration) has policies in place to advise businesses on how to deal with hazardous conditions that can lead to …

Tips for Buying Scuba Tubing

When novice divers decide to start buying their own scuba gear, it shows a certain commitment. Yet there are some things new divers should know before buying diving equipment. One of the more important elements in a diver’s kit is scuba tubing/hoses, which are vital for breathing underwater. Unde…

Corrugated Tubing – Applications and Benefits

The commercial production and use of plastic corrugated tubing in the United States began in 1967, following the invention of corrugation extruding machines in the early 1960s in Germany and designs made by Ira Clement in 1966 for Penn Tube Plastics in Pennsylvania. Initially made from polyethyle…