When two or more electrical cables or wires are bound together, the process is often referred to as bundling. There are several other terms used to describe this method for organizing wiring, including cable management systems, structured cable systems or simply structured wiring. Bundling serves as a means to organize cables so that they don’t become a tangled mess, and so individual wires can easily be traced back to their source.

Wire bundles are commonly used in offices, factories, data centers and other commercial or industrial buildings. Bundling is used in a range of applications to efficiently organize cables and from equipment, machinery, security systems or even for IT networks. In essence, bundling creates a functional plan to keep cables safe and organized. There are a number of different methods for bundling, but one of the best ways to bundle wiring or cabling involves spiral wrap.

What is Spiral Wrap & How is It Used?

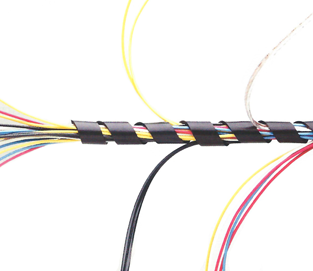

Whether it’s called spiral wire wrap, spiral wrap tubing, spiral cable wrap or just spiral wrap, it serves the same basic purpose. It serves to protect, organize and maintain cables, hoses, wires and other such implements. Spiral wrap is often used in place of other methods for bundling as it allows easier repair, replacement or rerouting of cabling without having to disconnect pieces of equipment powered by wiring from the bundle. This enables maintenance teams to more efficiently modify systems that rely on these bundles.

How to Install Spiral Wrap

Though it doesn’t require tools, using a flexible tape measure is helpful in measuring the diameter of bundles, as this measurement helps determine what size spiral wrap is needed. Installing spiral wrap around bundles of wiring involves just a few basic steps.

- Measure the cable bundle’s external diameter.

- Ensure the spiral wrap’s diameter is smaller than the bundle’s so that it won’t slip.

- Cut spiral wrap to the length needed.

- Wrap spiral wrap around the bundled wiring, beginning at one end and working toward the other end in a manner similar to how electrical tape is applied.

- Reroute any individual wires as needed outside the bundle.

Though rerouting individual cables is best done during installation, it’s still an easy task afterward. Rerouting after installation requires separating the spiral wrap just enough to remove the desired cabling and then leading it to where it’s needed.

Advantages of Spiral Wrap

Though zip ties, Velcro straps, electrical tape, nylon harnesses and other methods can be used to organize wire bundles, spiral wrap has unique properties that make it the best choice for many applications. Its ability to expand and retract as needed allows greater control of bundled cables, which allows bundles to more easily track around bends. Widening these gaps improves flexibility while decreasing gaps in spiral wrap improve resistance to abrasion and better insulates the wiring.

Advantages of using spiral wrap include:

- Allows room for alterations or repairs

- Easily removable

- Enables rerouting of cables or wires

- Expands and retracts as needed

- Increases lifespan of bundled cabling or wiring

- Insulates bundles

- Makes bundles more flexible

- Protects bundled cables or wires from abrasion

- Reusable

As spiral wrap is used to protect bundled cables from environmental hazards, its versatility makes it useful in numerous applications and industries.

Spiral Wrap Applications

The primary purposes for which spiral wrapping is used involve the organization and protection of bundles. Though methods like braided sleeving work well for these purposes, spiral wrap allows easier access to the individual cables within the bundles. It’s this versatility that makes spiral wrap particularly useful for any application where repairs or maintenance need to be done often or quickly.

Though most used for cable bundling, spiral wraps can also be used to protect hydraulic, industrial and pneumatic hose assemblies as well. Heavy-duty spiral wrap is even used underground to protect hoses in the mining industry. In a similar manner, it’s also used by automotive manufacturers to wrap hydraulic hoses in vehicles to protect against puncture or abrasion.

Spiral wrap is often used in the following applications and industries:

- Aeronautics industry

- Automotive industry

- Communications and computer networks

- Construction industry

- Electrical control systems

- Electro-mechanical assemblies

- Industrial robots and automated factories

- Mining industry

- Wire harness assemblies

Spiral wrap comes in various sizes, and can often be cut to length to fit the application. As spiral wrap protects cable bundles from various environmental hazards, it’s also necessary to choose the right material. Certain materials work better under specific conditions.

Spiral Wrap by Material

Certain applications may require spiral wrap made from material that can withstand harsh chemicals or extreme temperatures. Polyamides (nylon) and polyethylene are two of the most common materials from which spiral wraps are made. PTFE is a high-end, expensive material that offers some excellent protection.

Nylon spiral wrap is used to protect bundles of hoses in vehicle engines and in industrial applications, while also being used for cable bundles in electrical enclosures. In applications where the risk of fire is high, nylon also has self-extinguishing properties and won’t release toxic gases when exposed to flames. Nylon spiral wrap works best between operating temperatures of -40 °F to 250 °F (-40 °C to 121°C).

A more cost-effective material, polyethylene is highly abrasion resistant and is not affected by most solvents. Polyethylene is ideal for general applications with a temperature range of -76°F to 190°F (60°C to 88°C). Polyethylene can also come with UV Resistance or Fire Resistance.

While not used as widely for spiral wrapping bundles, polytetrafluoroethylene (PTFE) has an extraordinarily wide operational temperature range, capable of functioning in temperatures of -450°F to 500°F (268°C to 260°C). More widely known by its brand name, Teflon, PTFE’s advantages include its inflammability and chemical inertness & UV resistance.

M.M. Newman Corporation’s Heli-Tube® Spiral Wrap

M. M. Newman Corporation manufactures and sells Heli-Tube® spiral wrap made from nylon, polyethylene (including a fire-resistant variety) and PTFE. The company can customize lengths according to customer specifications, along with providing spiral wraps with specially made wall thicknesses, pitches and diameters. In addition to being functional, certain of its spiral wrap materials can be color-coded for aesthetics or to identify bundles.